For ASME SA182 F11 Insert weldolet, no matter what furnace than the temperature ranges up to 37 Degree F (3 Degree C) is termed as “refrigeration”. Alloy Steel F9 Coupolet intended for cryogenic service should be assembled in a clean room and be lubricant free, or utilize lubricants compatible with cold service.

WE ARE AN ISO 9001:2008 CERTIFIED COMPANY

-

Call us anytime

+91 77000 66688

-

Opening time

Mon - Sat 10.00 to 07.00

-

Email us now

sales@versatileoverseas.com

ASTM A182 F9 Olets

Alloy Steel F9 Threading Outlet Price, UNS K90941 Flexolets Distributors, DIN 1.7386 Brazolet Trader, Alloy Steel F9 Nippolets Dealer, Alloy Steel F9 Latrolet Manufacturer in India.

Table of Contents

- F9 Alloy Steel Outlet Fittings Types

- Alloy Steel F9 Weldolet

- Alloy Steel F9 Threadolets

- Alloy Steel F9 Nippolets

- ASTM A182 F9 Alloy Steel Flexolets

- Alloy Steel F9 Sweepolets

- Alloy Steel F9 Sockolets

- Alloy Steel ASTM A182 F9 Latrolets

- Alloy Steel F9 Welding Outlet

- ASME SA182 Alloy Steel F9 Branch Outlets

- Alloy Steel F9 Olets Specification

- Alloy Steel F9 Olets Chemical Composition

- Alloy Steel F9 Olets Mechanical Properties

- Alloy Steel F9 Outlet Fittings Equivalent Grades

- Countries We Export Alloy Steel ASTM A182 F9 Olets

- ASTM A403 Alloy Steel F9 Olets Other available Types

- Alloy Steel F9 Olet Fittings Application

- ASTM A182 F9 Elbolets

- ASTM A182 F9 Alloy Steel Brazolet

- Alloy Steel F9 Socket Welding Outlet

Alloy Steel F9 Socket weld Outlet Exporter, Alloy Steel F9 Nipple Outlets, ASTM A182 F9 Threadolets, Alloy Steel F9 Weldolet in India.

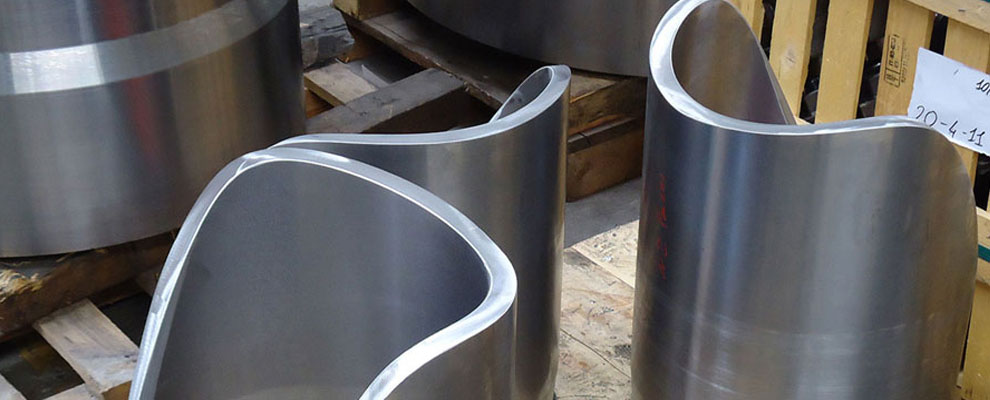

Versatile Overseas is a standard supplier of AS F9 Olets, which may be used for isolation and throttling services. Alloy Steel F9 Welding Outlet opens by lifting a round or rectangular gate/wedge out of the path of the fluid.

The distinct feature of ASTM A182 F9 Threading Outlet is the sealing surfaces between the gate and seats are planar. Alloy Steel F9 Socket Weld Outlet are often used when a straight-line flow of fluid and minimum restriction is desired. ASME SA182 F9 Flexible Outlet are primarily used to permit or prevent the flow of liquids. Alloy Steel F9 Nipple Outlet shouldn't be used for regulating flow, unless they are specifically designed for that purpose. ASTM A182 F9 Sweepolet generally is accepted in the oil and gas industry that the cryogenic temperature range starts at -238° F (-150° C). In addition to this temperature range for Grade F9Latrolet, certain gases are considered “cryogenic” because they take more than just an increase in pressure to compress their volume.

Specification Of Alloy Steel F9 Olets

| Specifications | ASTM A182 / ASME SA182 |

|---|---|

| Olets Size | 1/8"-4" (DN6-DN100) |

| Olets Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Olets Connect Type | Welded, threaded, BW, SW |

| Specialized manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| Olets uses & application | |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 Test Certificates certifying NACE MR0103, NACE MR0175 | |

Alloy Steel F9 Olets Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy Steel F9 | 1.7386 | K90941 |

Alloy Steel F9 Olets Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.50 - 1.0 | 0.030 max | 0.030 max | 8 – 10 | 0.9- 1.1 |

Alloy Steel F9 Olets Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy Steel F9 | 380 | 585 | 20 % |

ASTM A182 F9 Olets Manufacturing Standards in India & Worldwide

| Standard | Description |

| ASTM A182 | Standard Specification for Alloy Steel F9 Outlet Fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded Outlet fittings |

| MSS SP 79 | Standard Specification for Alloy Steel F9 Insert Welding Outlet |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

| JIS B2316 | socket-welding outlets pipe fittings |

Alloy Steel F1 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Alloy Steel F1 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Alloy Steel F1 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F1 Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F1 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F1 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Alloy Steel F9 Olets Other Available Products

| AISI F9 Alloy Steel Olet Fittings | Alloy Steel F9 Brazolet |

| ASTM A182 Alloy Steel F9 Weldolet | Alloy Steel F9 Threading Outlet Stockist |

| Alloy Steel Weldolet Suppliers | Alloy Steel F9 Latrolet in India |

| Alloy Steel A182 F9 Threadolet | Alloy Steel F9 Branch Outlets Distributors |

| ANSI B16.9 Alloy Steel F9 Latrolets Stockholder | Alloy Steel F9 Sweepolet |

| ASTM A182 F9 Alloy Steel Nipple Outlet | ASME B16.5 Alloy Steel F9 Elbolet |

| ASME SA 182 Alloy Steel F9 Welding Outlet | Alloy Steel F9 Branch Connection |

| Alloy Steel F9 Flexible Outlet | ANSI/ASME B16.5 Alloy Steel F9 Socket Weld Outlet Exporter |

| Alloy Steel F9 Outlets Price List | F9 Alloy Steel Nippolet Dimensions |

| Alloy Steel ASTM A182 F9 Sockolet | Alloy Steel F9 Flexolet |