WE ARE AN ISO 9001:2008 CERTIFIED COMPANY

-

Call us anytime

+91 77000 66688

-

Opening time

Mon - Sat 10.00 to 07.00

-

Email us now

sales@versatileoverseas.com

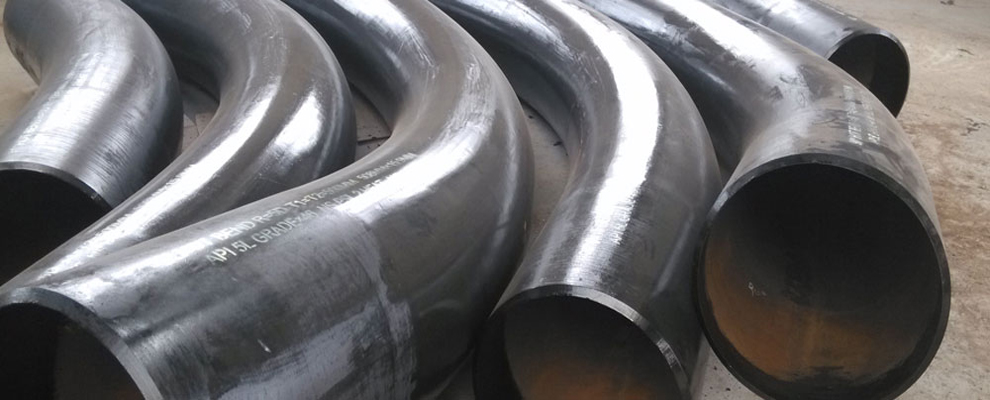

ANSI / ASME B16.9 Piggable Bend

Check BS1560 Piggable Bend, ASME B16.9 Piggable Bend Price List, MSS SP-43 Piggable Bend, Carbon Steel Piggable Bend, Alloy Steel Piggable Bend SCH 40, 5d Pipe Piggable Bend SCH 10 & Sch 80, DIN 2605 Seamless Piggable Bend Supplier in Mumbai, India.

We are an acknowledged supplier and exporter of Piggable Bend Pipe Fittings, which are very much resistant to corrosion and have the utmost strength to density ratio of any metal. Stainless Steel Piggable Bend Pipe Fittings have a high temperature treatable and have high strength and ductility together with unsurpassed weldability and fabricability. With regard to its one of its kind density, strength and corrosion resistance, Carbon Steel Piggable Bend Pipe Fittings has found applications in several industries. For high quality tubing products, Alloy Steel Piggable Bend Pipe Fittings is usually a better material to use than the challenging materials like steels. Super Duplex Steel Piggable Bend Pipe Fittings is a metal added in the making of a joint through welding, brazing, or soldering. Air frame applications, chemical industry, and skins applications are some for Inconel Alloy Piggable Bend Pipe Fittings to name a few where highest formability is needed through moderate strength.

Monel Alloy Piggable Bend Pipe Fittings are quite recognized moderately all over as a high-strength and low-weight material, which has approximately 60 percent of steel in it. However, Hastelloy Alloy Piggable Bend Pipe Fittings has other extraordinarily attractive properties also such as most amazingly high corrosion resistance, and supreme electrical conductivity. These Nickel Alloy Piggable Bend Pipe Fittings are used for different applications in industries such as Steel, Shipbuilding, Petrochemical, and so on.

Alloy Seamless Piggable Bend, Duplex Steel Piggable Bend, 1/2 to 48 Inch Piggable Bend Short Radius Exporter, Inconel Piggable Bend, ANSI B16.9 Piggable Bend LR Dimension, Carbon Steel Piggable Bend, Nickel Alloy Piggable Bend Manufacturer in India.

Specification Of Piggable Bend Fittings

| Barred Piggable Bend Pipe Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

|---|---|

| Piggable Bend Fitting Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Piggable Bend Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Piggable Bend Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Grooved Piggable Bend Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Piggable Bend Fitting Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Piggable Bend Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Piggable Bend |

|

| Application |

|

| Stainless Steel Piggable Bend | ASTM A403 WP316, 316L, WP304, 304L, ASTM A182 F316L, 304L, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Alloy Steel Piggable Bend | ASTM A234, ASME SA234 WP1, WP5, WP9, WP11, WP22, WP91 |

| Super Duplex Piggable Bend | ASTM A815 / ASME SA815 UNS No S32750, S32950 |

| Duplex Steel Piggable Bend | ASTM A815 / ASME SA815 UNS No S31803, S32205 |

| Nickel Alloy Piggable Bend | ASTM B336, ASME SB336, Nickel 200 (UNS N02200), Nickel 201 (UNS N02201), Monel 400 (UNS N04400), Monel 500 (UNS N05500), Inconel 800 (UNS N08800), Inconel 825 (UNS N08825), Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 601 (UNS N06601), Hastelloy C 276 (UNS N10276), Titanium (Grade I & II), Alloy 20 (UNS N08020), Cupro Nickel 70/30, CuNi30Mn1Fe, CuNi10Fe1Mn. |

| Carbon Steel Piggable Bend | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Piggable Bend | ASTM A420 WPL3, A420 WPL6 |

Buttweld Piggable Bend Fittings Types

| 6D pipe Piggable Bend SCH 10 | 180 degree Piggable Bend, Schedule 80, 6 Inch | Inconel Piggable Bend SCH 40 |

| ASTM A234 WPB, Piggable Bend, BW, ANSI B16.9 | Piggable Bend Sch 80 ASTM A234 WPB | Monel Piggable Bend, SCH40, BW |

| ASME B16.9 Piggable Bend 6 IN | ANSI B16.9, Butt Welded Piggable Bend | ANSI B16.9 Piggable Bend LR A403 WPB, 12 Inch |

| MSS SP43 Piggable Bend | SCH 60, 16 Inch ASTM A234 WPB Piggable Bend | Piggable Bend, 5d |

| SCH 40, Black, A234 WPB Piggable Bend | DIN 2605 Piggable Bend | 10 Inch, SCH 40, LR Pipe, A403 WPB Piggable Bend |

| Carbon Steel Piggable Bend | B16.9, DN200, SCH 40, BW Ends, Piggable Bend | ANSI B16.9 Piggable Bend WPHY 60 |

| A403 Gr WP304 Piggable Bend Mitered | AWPHY 65, SCH40, BW, Piggable Bend | ASTM A403, SCH 40, 1 Inch, Piggable Bend |

| WPHY 70 Smls Piggable Bend Sch 80 Stockist | BS1560 Piggable Bend Mitered | DIN 1.0619 Piggable Bend |